In many manufacturing and commercial environments, maintaining proper airflow is crucial to ensure efficiency, equipment longevity, and worker comfort. As part of our commitment to innovation and performance, we at Gaowei Group focus on developing reliable ventilation systems that address these industrial needs effectively. Working as professional ventilator equipment manufacturers, we have continuously optimized our product lines to meet the specific demands of different operational environments. When it comes to industrial ventilation, one of the most common questions we encounter is: What is the difference between an industrial fan and an exhaust fan?

How Industrial Fans Support Large-Scale Air Circulation

An industrial fan is primarily designed to move large volumes of air within a workspace. Its purpose is to promote consistent air circulation, regulate temperature, and prevent stagnant air accumulation in production facilities, warehouses, or assembly lines. As experienced ventilator equipment manufacturers, we design industrial fans to handle continuous operation with stable performance and efficient airflow distribution. These fans are ideal for situations where airflow management is required across wide areas, helping improve working conditions and support equipment cooling.

Our industrial fans are built with durable components to ensure operational safety and reliability. For example, at Gaowei Group, we incorporate advanced motor systems, reinforced blades, and optimized structural design to achieve steady airflow while maintaining energy efficiency. This design focus allows our industrial fans to provide high performance under demanding conditions, minimizing downtime and maintenance requirements for our global B2B clients.

The Role and Advantages of Industrial Exhaust Fans

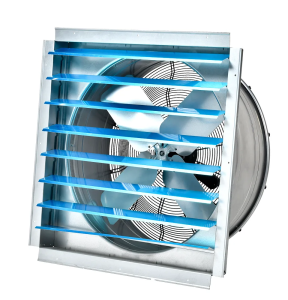

While industrial fans manage air circulation, industrial exhaust fans are responsible for removing unwanted air, such as heat, smoke, moisture, or dust, from enclosed spaces. The industrial exhaust fan manufactured by Gaowei Group features a galvanized steel housing, ensuring strong resistance to rust, heat, and wear over time. Equipped with a high-quality inserted motor, the fan delivers high air volume, excellent efficiency, and low noise operation while consuming less energy. Its easy installation and long-lasting structure make it a practical choice for industrial, commercial, and agricultural facilities — including warehouses, workshops, and farms.

For instance, one of our industrial exhaust fan models offers an input power of 570 W, a rotation speed of 1050 RPM, and an air volume capacity of 5500 m³/h. With a size of 954 × 954 × 388 mm, it fits easily into various structural settings without sacrificing performance. This combination of design and efficiency ensures dependable ventilation even in high-demand environments, supporting better air quality and operational stability.

Conclusion: Choosing the Right Solution for Your Application

The key difference between industrial fans and exhaust fans lies in their core functions—air circulation versus air removal. Both, however, are indispensable to maintaining safe and efficient industrial environments. As one of the dedicated ventilator equipment manufacturers, we at Gaowei Group take pride in providing products that balance power, durability, and practicality. Our solutions are designed with flexibility in mind, meeting the ventilation requirements of clients across manufacturing, agriculture, and commercial sectors.